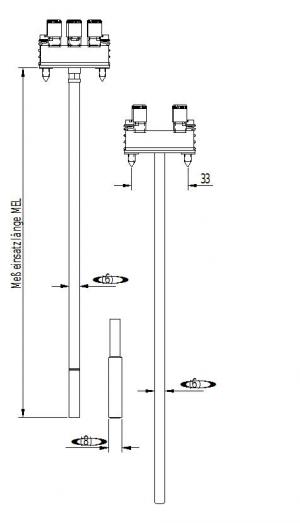

Structure of the inset:

according to DIN 43735 for thermocouples. Basic values according to DIN EN 60584 in Tolerance class 2 or 1. Thermocouple 1 x or 2 x Type “J” or “K”.

In rigid version with thermocouple wire in ceramic insulation rod and protective tube, 6.0 or 8.0 mm of stainless steel.

In flexible version with mineral insulated sheathed cable, highly compressed MgO powder, external protective sheath of material 1.4541 or Inconel 2.4816.

Terminated with shelf plate and terminal block. (For variants please refer to the worksheet).

Design of the thermocouples:

Temperatures up to 600°C standard, with rigid protective tube made of stainless steel, Inconel or Nickel for higher temperatures. In flexible version up to 600°C standard with stainless steel for all thermocouples, over 600°C with sheathed cable of Inconel material with internal thermal wire pair of iron constantan Fe-CuNi Type “J” and Type “L” up to 900°C, NickelChrom-Nickel NiCr-Ni Type “K” and NickelChromSilicium-NickelSilicium

Type “N” up to 1250°C. For variants up to 1600°C, PlatinRhodium-sheath for PlatinRhodium-Platin PtRh-Pt Types “S” and “B”. Up to 2300°C, molybdenum sheath for TungstenRhenium-TungstenRhenium Type “C” and “A”. For other thermocouples, refer to the worksheet or ask our technical customer service.