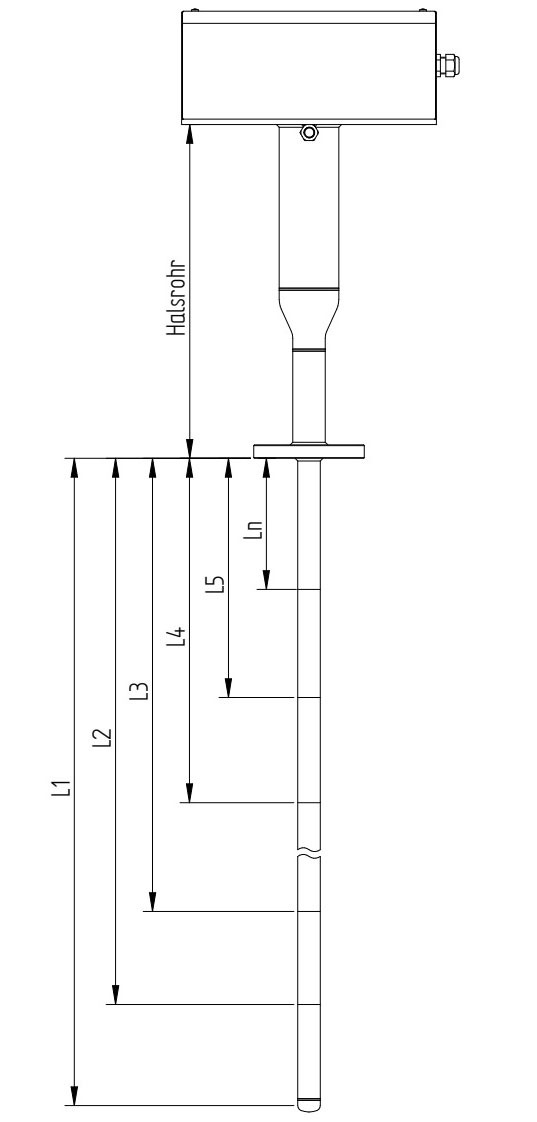

Stufen-Widerstandsthermometer, Typ “W-M 100 (150,250,450,630 ) FHaKa“

In starrer Ausführung mit individuell konfektionierbarer Anschlussmöglichkeit

Set-up:

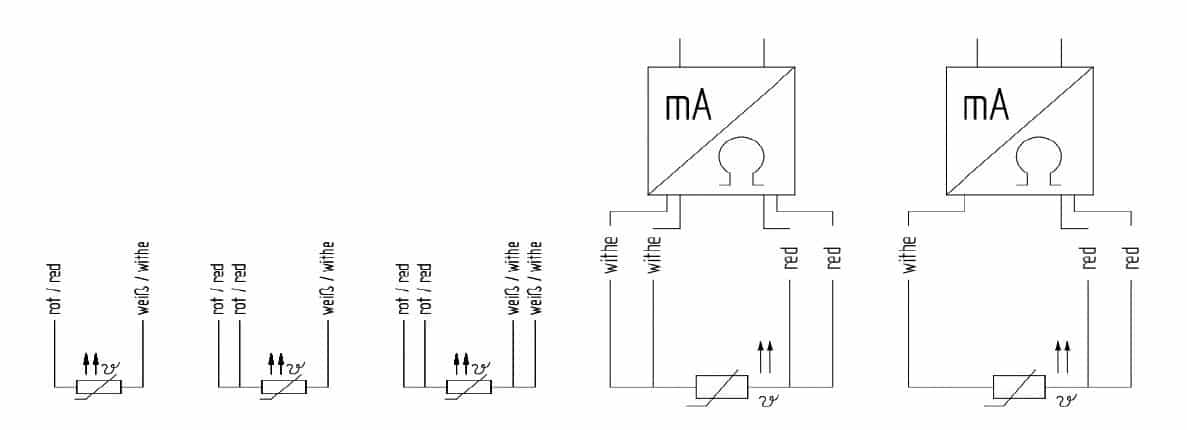

Resistance thermometer 1(or number n=x) Type “Pt100” or “Pt1000”, performance according to DIN EN 60571, Tolerance class B, A or better, installed in an SS protective sleeve, extended with MI cable, insulation made of highly compressed magnesium powder.

Installed in a protective fitting made of stainless steel or Inconel,e.g. with connecting flange, neck tube and connecting box with cable gland connections and installed series terminals, measurement transmitters are also possible.If required the cable gland connections can also be replaced by various plug versions.

Other process connections or designs not listed here, can also be supplied. (For other options, please refer to the worksheet).

Specification of sensors and max. recommended temperature loading for the sensor type:

Pt100 / 1000, tmax. 600°C

For an improved response time, the sensors can be connected under certain conditions with the inner walls of the protection sleeve; see special designs section or ask our technical customer service department.

Areas of Application

Chemicals: in vessels & reactors

Petrochemicals: in catalyst filling and in distillation columns

Research: In laboratories and technical facilitiesfor media such as gases, vapours and liquids